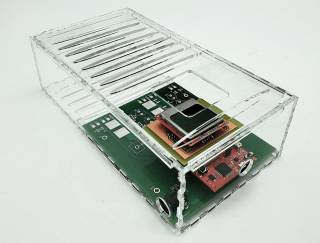

Tomi Roinila, tenure-track professor of power electronics at the Faculty of Information Technology and Communications, is one of the researchers using FabLab. Most recently, he completed a frame for electronic circuits used in the research laboratory. The piece will be utilized in a project to develop new technology for battery recycling and new use.

– In these frames, it was important to achieve millimeter-accurate sizing and the right kind of perforation for later placement and use of the frames. I used laser cutter to make the frames, which is very precise machining of different materials, Tomi Roinila says.

– In these frames, it was important to achieve millimeter-accurate sizing and the right kind of perforation for later placement and use of the frames. I used laser cutter to make the frames, which is very precise machining of different materials, Tomi Roinila says.

He appreciates the opportunity to produce the parts by himself on the campus.

– Obtaining products from commercial operators would have been slow and expensive, Roinila says.

By experimenting you learn

Since few have laser cutters or 3D printers in everyday use, getting started can be exciting. Tomi Roinila encourages his research colleagues to try boldly.

– Getting started may feel difficult if you have no previous experience. Actually it is easy to start working in FabLab. Know-how grows quickly with fuss. FabLab staff is really service-minded and nice, you can always ask for help, he says.

– The devices enable really precise machining of different sizes and high-quality materials. FabLab has wide selection of materials available. This creates wide possibilities to use FabLab not only in research but also in my own hobbies, Roinila suggests.

The frame was completed routinely.

– The device is easy to use. I made the first prototypes with wood material, which is inexpensive and easy to handle. I have already enough experience, so no surprises came up, the researcher inches.

– I get excited every time I come to FabLab. The next project is not yet tied up, but I am sure to have new ideas pretty soon.