1. Tell us a bit of yourself.

I am Lari Kuuppo, Master’s degree student in materials department.

2. What you made at FabLab this time? What was FabLab’s role in the process? (platform, expertise, etc.)

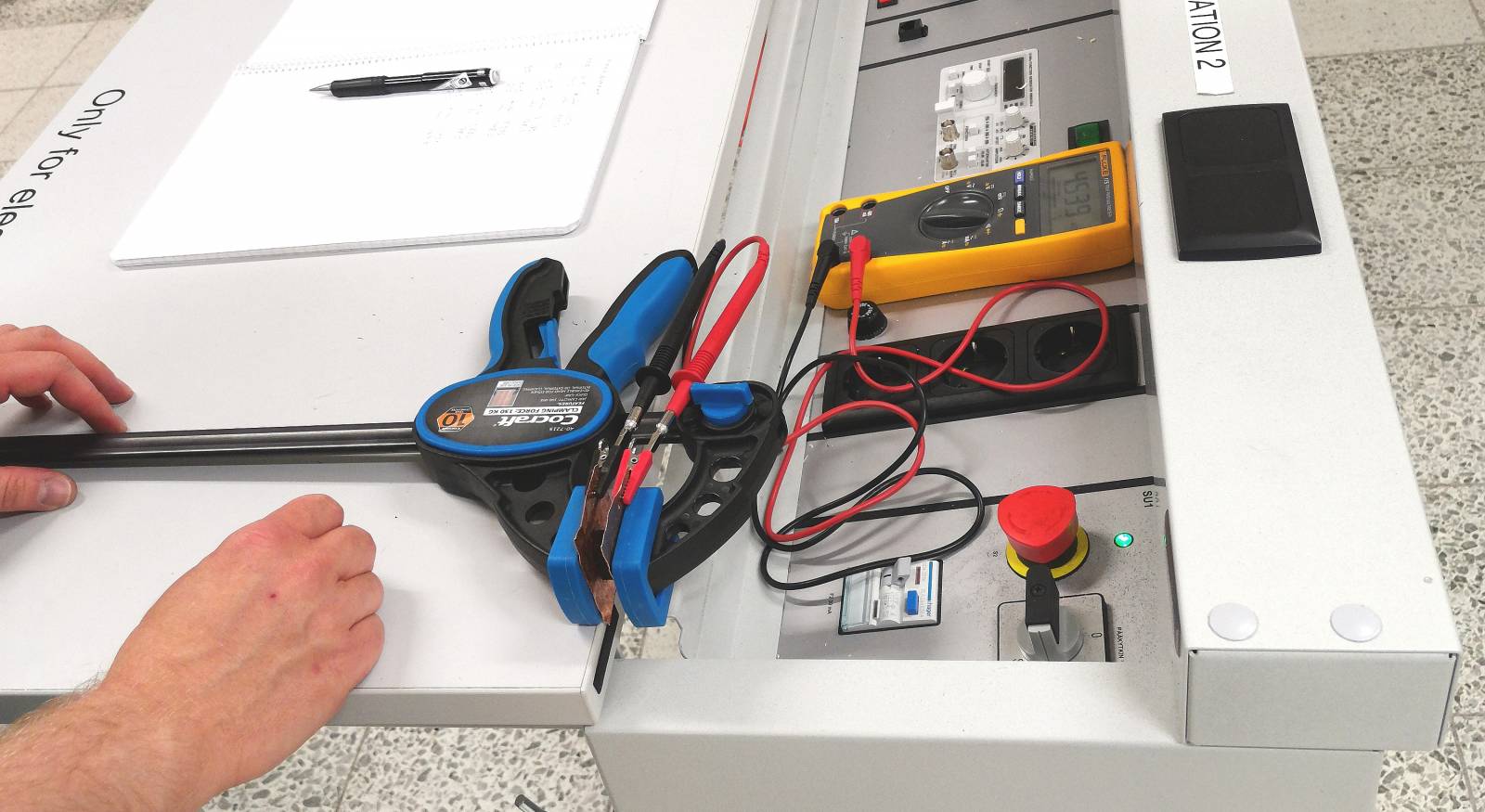

I did the work related to my thesis: First I printed the pieces with a 3D printer, then I measured their resistance with a multimeter on the electronic desk.

3. Did you have any surprises along the way? Did the work go as you expected?

Surprises came mostly when working with 3D printers. Sometimes the songs did not print as expected, sometimes the printer nozzle became clogged. Because the work was experimental in nature, it was expected that not everything would go according to plan. However, the problems were solved and eventually the work was successful.

4. How the item you produced is utilized in the research?

This thesis and related work at FabLab is used in inversion algorithm research and mathematical modeling.

5. Do you already know what to do next at FabLab?

It would be interesting to study the effect of 3D printer parameters on the internal structure of a part even more, but in the framework of this work it is no longer possible.

6. What would you like to tell those who are still considering using FabLab?

FabLab should definitely be used in studies and research. There is a wide variety of machines and equipment there, and the staff has a wide range of expertise. I recommend to use their expertise.